Polyurea

SG E375-08 Marine Grade Polyurea Barrier System

The Marine Grade Polyurea, SG E375-08 spray Polyurea system is designed to encapsulate treated lumber and timber piles to prevent preservatives from migrating into the environment and protecting the lumber and timber piles from abrasion and mechanical damage. Polyurea – SG E375-08 spray Polyurea water barrier system can be used for encapsulating ACZA, CA-C, CCA, and other wood treatments for use aquatic and wetland environments.

The Marine Grade Polyurea, SG E375-08 spray Polyurea system is designed to encapsulate treated lumber and timber piles to prevent preservatives from migrating into the environment and protecting the lumber and timber piles from abrasion and mechanical damage. Polyurea – SG E375-08 spray Polyurea water barrier system can be used for encapsulating ACZA, CA-C, CCA, and other wood treatments for use aquatic and wetland environments.

SG E375-08 Marine Grade Water Barrier System provides exceptional monolithic bonding to the treated wood products. Thunderbolt Wood Treating utilizes the industries BMP (Best Management Practices) methods and processes and in conjunction with our coating process, we provide a focus on being environmentally responsibility.

SG E375-08 Marine Grade Polyurea Barrier System is recognized and approved by the California Coastal Commission, American Wood Protection Association, Western Wood Preservers Institute, California Association of Harbor Masters & Port Captains, Pacific Coast Congress and other government agencies.

We eliminate the need to wrap treated timber pilings at the jobsite and prior to installation. Our treated and coated lumber and timber piles arrive ready to install and remains fully adhered during installation minimizing the installation time.

Helping Our Environment

Proven long term performance in marine applications, SG E375-08 is designed to encapsulate and prevent the leaching of treating products into our waterways.

Leaching Rates, Subsequent Exposures and Model Evaluation

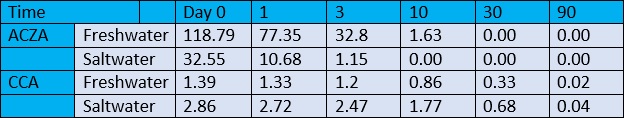

This section will briefly present information on leaching rates of treated wood products, models developed to predict leaching rates and subsequent concentrations in sediments. The ACZA formulation is often for in-water portion of structures. The leaching of copper from ACZA treated wood products demonstrates a general trend of higher initial leaching rates that decrease rapidly within days. Within a few weeks to months, copper leaching decreases to very minute levels.

Leaching rates (ug/cm²/day) of a single 15 cm diameter piling, Freshwater salinity 0 ppt, Saltwater salinity 30 ppt.

SG E375-08 Marine Grade Polyurea Barrier System can provide a practical cost effective solution for projects that require marine protection, long term durability and an innovative approach to today’s environmental concerns. SG E375-08 contains PTMEG and has been engineered for marine environments and is self-leveling to provide a smooth surface and its gel time promotes better adhesion to timber products. SG E375-08 is used in a variety of marine or non-aquatic applications and has a proven record of substantial durability.

PTMEG is used in high performance systems when longevity is required in harsh environments. The innovative Polyurethane Intermediates Terathane® PTMEG is a premium polyether glycol and is used as a soft-segment building block in high performance polyurea, polyurethanes, polyesters, and other polymers. It is available in a wide range of molecular weight (from 250 up to 2900) and provides outstanding dynamic properties, low temperature flexibility, and hydrolytic stability.

SG E375-08 Benefits

- Designed for use in harsh marine environments.

- History of worldwide use in a variety of marine environments from. Greenland to Jakarta and from cold to warm humid environments.

- The manufacturer produces this product for use in their product line – Ocean Guard and Ocean Cushing, Foam-filled Fenders.

- Monolithic, fully adheres to the contours of the timber surface.

- No additional wrapping required.

- US Navy Approved.

- Environmentally friendly, 100% solids.

- Arrives at jobsite ready to install.

We can proved the experience, guidelines, references, and specifications to fit your project